GRP Lining for Tanks and Manholes

- Home

- GRP Lining for Tanks and Manholes

GRP Lining – Corrosion Protection and Waterproofing Solutions – MANYCON CONTRACTING COMPANY

Advanced GRP Lining for Superior Corrosion Resistance and Waterproofing in Saudi Arabia

MANYCON CONTRACTING COMPANY in Saudi Arabia, we're dedicated to delivering top-notch GRP lining solutions that shield surfaces from corrosion, chemical attack, and moisture infiltration. Our certified team expertly applies durable GRP linings to tanks, pipelines, and industrial structures, ensuring long-term protection in even the most demanding environments. From Riyadh to Dammam, Jubail, and beyond, we're the trusted partner for industries seeking reliable, high-performance solutions

What Is GRP Lining?

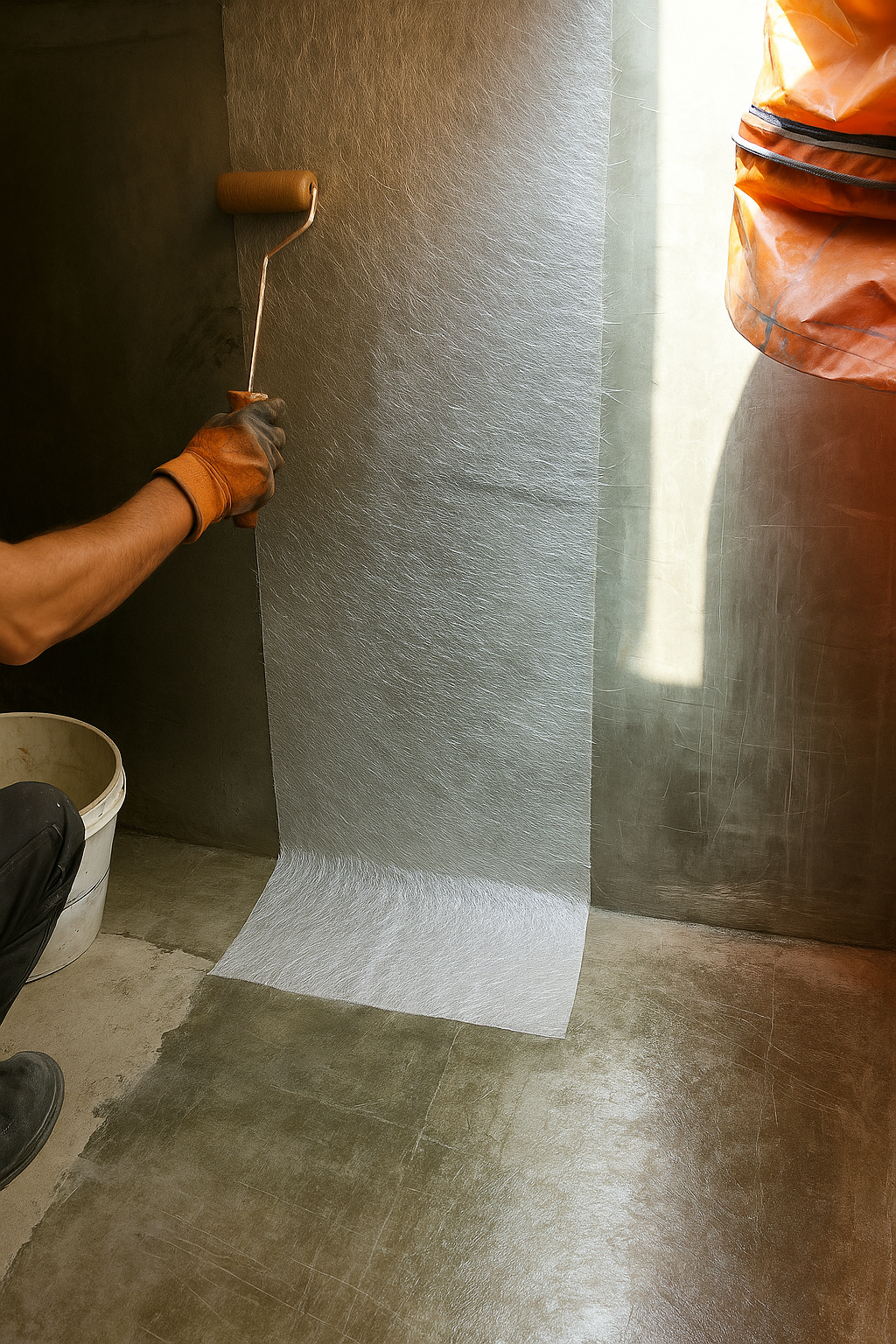

GRP lining involves applying a composite material made from glass fibers and resin onto a surface to form a seamless, corrosion-resistant barrier. This method is ideal for environments exposed to chemicals, saltwater, and high humidity, providing both waterproofing and structural reinforcement.

Key Benefits:

- Outstanding resistance to corrosion, chemicals, and abrasion

- Seamless waterproofing solution for industrial applications

- Reinforces and extends the life of surfaces and assets

- Easy to clean, maintain, and repair when necessary

- Suitable for a wide range of substrates and environments

🔧 Our GRP Lining Services Include:

Tank Lining and Waterproofing

GRP linings for potable water, sewage, and chemical storage tanks to prevent leakage and internal corrosion.

Pipeline Lining

Internal GRP coatings for industrial and municipal pipelines to protect against pressure, chemicals, and erosion.

Concrete and Metal Surface Protection

GRP reinforcement for concrete basements, sumps, clarifiers, and steel surfaces to resist aggressive conditions.

Chemical Storage and Waste Management Systems

GRP lining of tanks and treatment plants handling hazardous or corrosive materials to ensure environmental safety.

Marine and Offshore Applications

Corrosion-resistant GRP coatings for ships, platforms, and marine facilities exposed to saltwater and humidity.

Post-Lining Inspection & Maintenance

Routine inspections and repairs to ensure continued performance and structural integrity of GRP-lined areas.

📐 Technical Details of GRP Lining Systems

🔸 Materials Used:

- Glass Reinforced Plastic (GRP) – A strong, durable composite combining fiberglass with high-performance resin

- Epoxy Resin – Used for its excellent chemical resistance and strong adhesion properties

- Polyester Resin – Cost-effective and durable option for general-purpose lining

- Vinyl Ester Resin – Superior performance in highly corrosive environments such as acid tanks or chemical plants

🔸 Application Method:

- Surface preparation (degreasing, abrasion, and cleaning)

- Lamination process using chopped strand mats or woven roving fiberglass

- Layer-by-layer resin application and curing

- Final testing and inspection to ensure adhesion, thickness, and waterproof integrity

🔸 Compliance & Quality:

Meets international standards: ASTM D638, ASTM D790, and ISO 9001

Engineered to comply with Aramco, SABIC, and Royal Commission project specifications

Adheres to local environmental and safety regulations for hazardous containment

🏢 Applications of GRP Lining:

Potable and Wastewater Storage Tanks

Chemical Storage Tanks and Vessels

Oil & Gas and Industrial Pipelines

Marine Structures and Ship Components

Concrete Clarifiers, Sumps, and Channels

Sewage and Wastewater Treatment Systems

🚀 Why Choose MANYCON Saudi for GRP Lining?

✅ Proven GRP systems with chemical, thermal, and corrosion resistance

✅ Advanced application techniques by certified GRP specialists

✅ Minimal downtime and non-intrusive installation

✅ Custom-designed solutions to meet your industry’s exact standards

✅ Reliable after-sales support, inspection, and maintenance programs

Quick Contact

📞 Protect Your Structures with Professional GRP Lining Solutions

Get in touch with MANYCON CONTRACTING COMPANY for a free consultation, technical evaluation, and a customized GRP lining proposal tailored to your needs: MANYCON CONTRACTING COMPANY